Industry/Process/Application

Intro Text, Trend, Teaser

Datos clave de la aplicación

Sector

Pruebas en línea de calentadores de alta tensión según las fases de fabricación

Aplicación

Comprobación del funcionamiento de la electrónica de control.

Parámetro medido

Tensiones de 100 a 900 V CC y corriente correspondiente

Condiciones esenciales

Se aplican tensiones de hasta 900 V CC, en función del producto sometido a ensayo

Las altas tensiones deben medirse con seguridad y precisión durante las pruebas de montaje o en línea.

Se requiere flexibilidad con la selección de la entrada de tensión para diferentes configuraciones de aplicación

Confirmación de la funcionalidad de la electrónica de control

Descripción de la aplicación

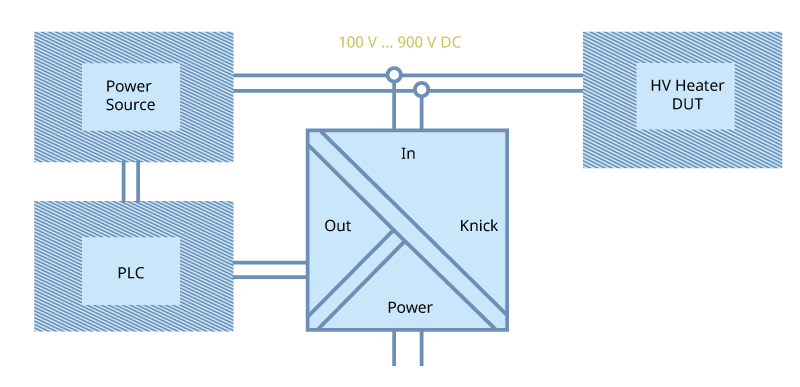

El proceso de producción de los HVH implica muchos pasos, siendo algunos de ellos manuales. Se realizan varias pruebas en línea, según las etapas de fabricación correspondientes. Dependiendo del tipo de calentador, se aplican tensiones de 100 a 900 V CC directamente sobre la unidad de la capa de calentamiento. Al mismo tiempo, se mide esta tensión y la corriente correspondiente para comprobar el funcionamiento de la electrónica de control. Dado que existe riesgo de descarga eléctrica, durante esta prueba no debe realizarse ningún montaje en la pieza de trabajo.

Requisitos de la aplicación

Para obtener resultados de ensayo fiables, es importante utilizar equipos de medición precisos y fiables. El uso de equipos de laboratorio en un entorno de producción no siempre resulta práctico. Por ello, para los bancos de pruebas de final de línea, además de en las fases de investigación y desarrollo, se utilizan dispositivos de alta calidad probados en aplicaciones industriales.

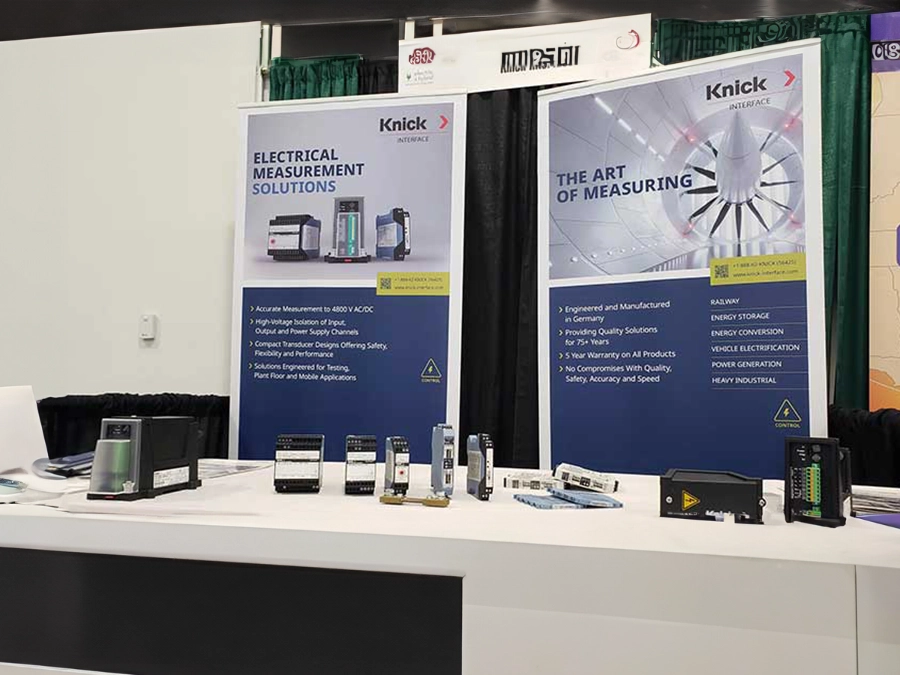

¿Por qué Knick?

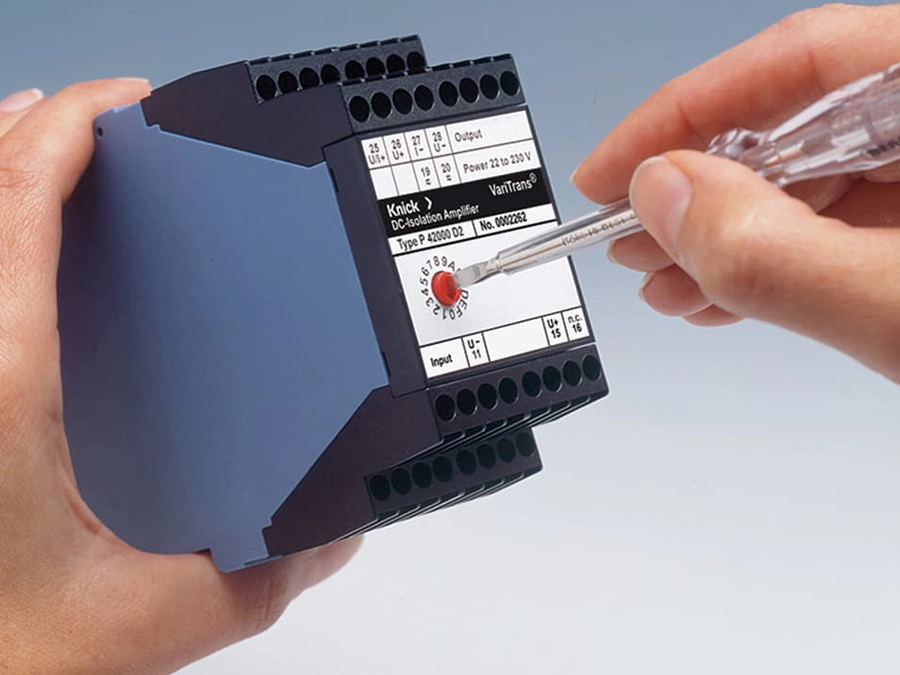

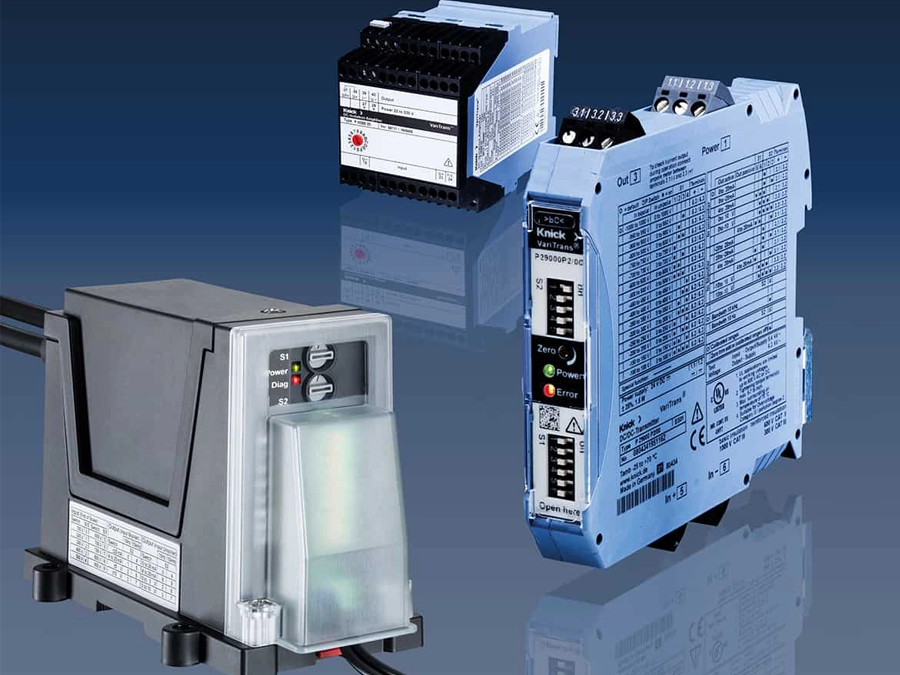

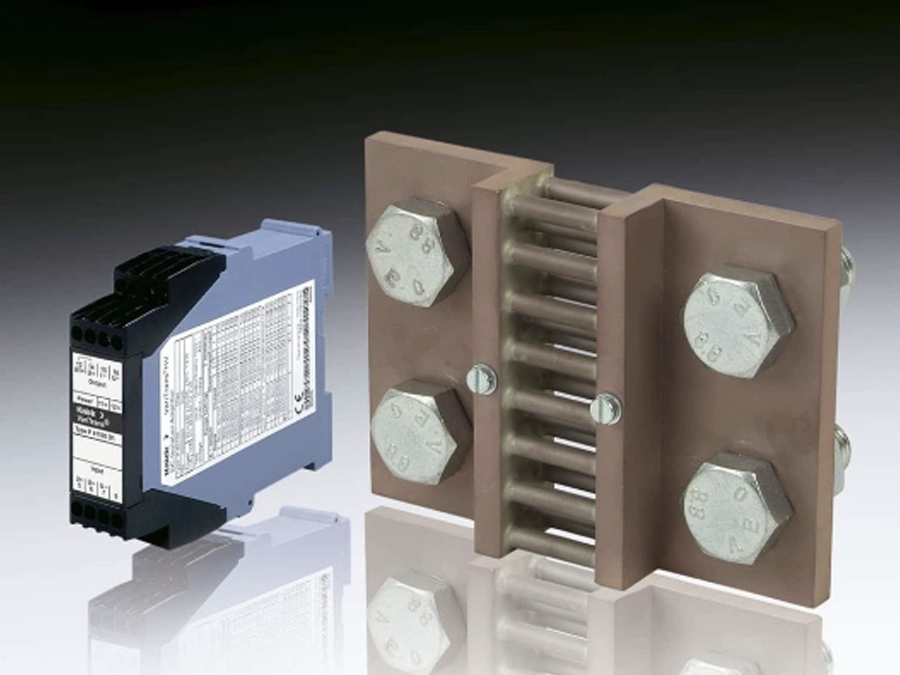

El Knick P29000 es un transductor de tensión que puede medir con seguridad tensiones de hasta 1000 V CC. La precisión se mantiene gracias a un error de ganancia < 0,2 % del valor medido. La seguridad se garantiza mediante un aislamiento eléctrico basado en un transformador de 3 canales a una tensión de trabajo de 1000 V CA/CC. La seguridad eléctrica adicional queda demostrada con la especificación de tensión de prueba del P29000 de 5,4 kV CA. La flexibilidad se obtiene mediante rangos de entrada y salida seleccionables a través de interruptores DIP integrados.

Headline H2

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet.

Headline H3

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet.

Productos relacionados

Industrias y aplicaciones relacionadas

E-Mobilty Broschüre

Titel des Dokuments (de) Donec pede justo, fringilla vel, aliquet nec, vulputate eget, arcu. In enim justo, rhoncus ut, imperdiet a, venenatis vitae, justo

E-Mobilty Broschüre

Titel des Dokuments (de) Donec pede justo, fringilla vel, aliquet nec, vulputate eget, arcu. In enim justo, rhoncus ut, imperdiet a, venenatis vitae, justo