Industry/Process/Application

Intro Text, Trend, Teaser

Fatti chiave dell'applicazione

Settore

Emulazione HIL per i test nello sviluppo del prodotto e nella prototipazione

Applicazione

Emulazione delle condizioni all'interno dei veicoli e degli effetti sui componenti ad alta tensione

Parametro misurato

Segnali standard 0-10 V e 0-20 mA per la funzione di controllo

Requisiti chiave

È necessario isolare le alte tensioni quando si eseguono test con un livello di potenza pari o superiore a quello di un veicolo.

È richiesto un controllo dinamico veloce, quindi è necessaria una trasmissione veloce del segnale.

È necessaria un'elevata precisione per ottenere risultati di prova di qualità

L'emulazione richiede un elevato isolamento in uscita

Diverso da quello tipicamente disponibile

Test di sistemi ad alta tensione

Descrizione dell'applicazione

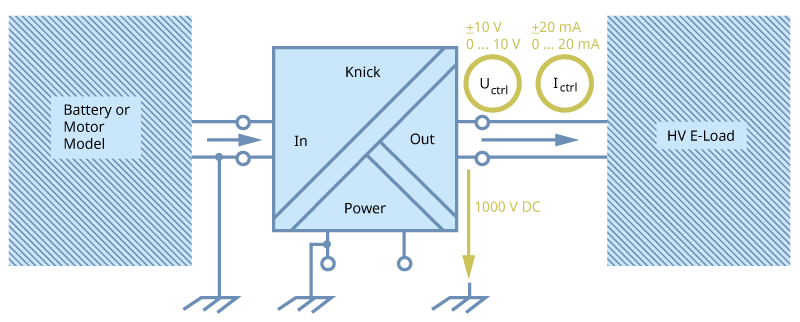

Un tempo, nelle applicazioni di condizionamento del segnale che coinvolgevano ambienti ad alta tensione, i requisiti di isolamento elettrico più estremi si riscontravano sul lato di ingresso della configurazione. L'uscita veniva poi spesso collegata a un sistema di controllo a bassa tensione. Tuttavia, con l'aumento delle applicazioni di test HIL (Hardware In The Loop) per l'elettrificazione dei veicoli, la sorgente di alta tensione si trova spesso sul lato di uscita della configurazione. I segnali vengono generati dai sistemi di collaudo per emulare le condizioni che si verificano all'interno del veicolo e quindi gli effetti sui componenti ad alta tensione che lo compongono.

Requisiti dell'applicazione

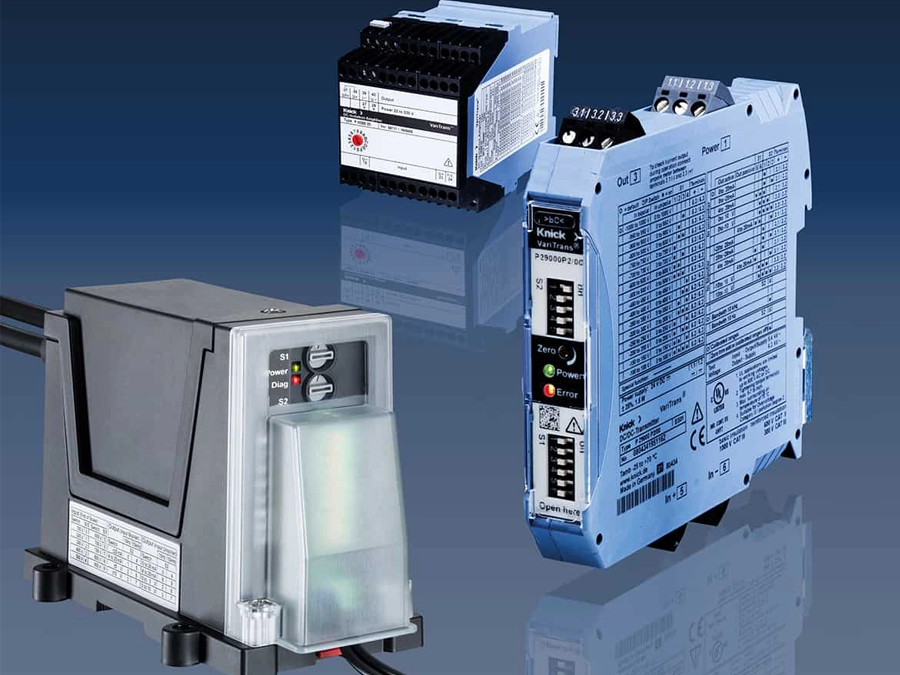

L'integrazione di dispositivi in grado di gestire i requisiti di conversione del segnale, isolando allo stesso tempo elettricamente tutti i canali, è fondamentale per la progettazione e le prestazioni del sistema HIL. L'emulazione di componenti in sistemi altamente dinamici richiede una trasmissione del segnale altrettanto veloce e precisa.

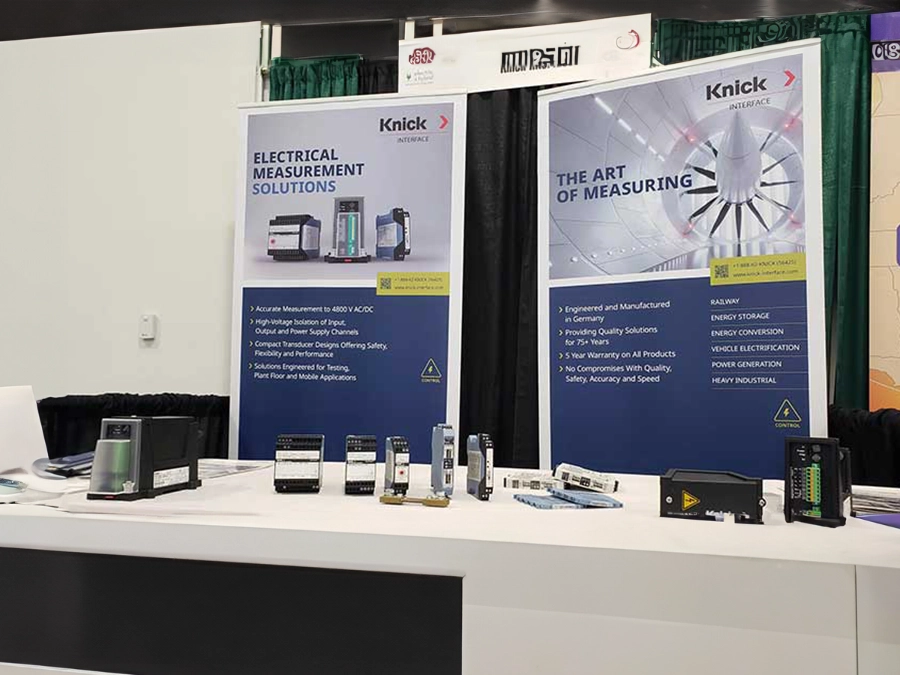

Perché Knick?

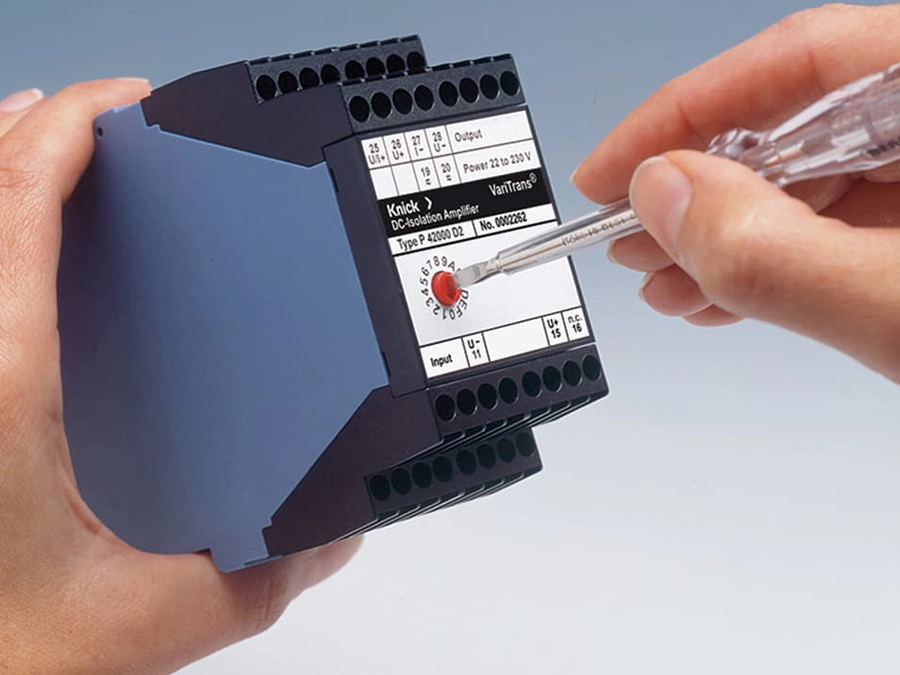

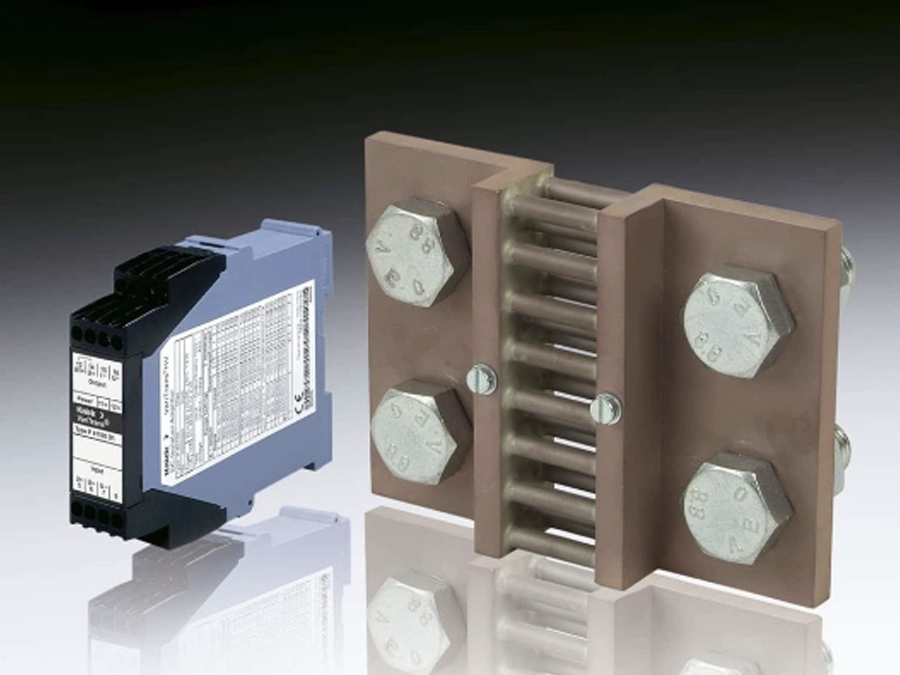

I Knick P15000 e A26000 (se sono necessarie misure bipolari) possono trasmettere segnali da un modello emulatore a potenziale di terra e inviarli alle apparecchiature in prova ad alto potenziale elettrico. L'elevato isolamento in uscita, pari o superiore a 1000 V, è la caratteristica decisiva di questa soluzione. Le dimensioni ridotte e l'impilabilità consentono il controllo di sistemi impilati in armadi di dimensioni ragionevoli. Il tempo di risposta del T90 è stimato in 70 μs e il dispositivo contiene una specifica di frequenza di taglio di 10 kHz. La precisione della conversione da ingresso a uscita è garantita da un errore di guadagno inferiore allo 0,1% del valore misurato.

Headline H2

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet.

Headline H3

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet.

Prodotti correlati

Industrie e applicazioni correlate

E-Mobilty Broschüre

Titel des Dokuments (de) Donec pede justo, fringilla vel, aliquet nec, vulputate eget, arcu. In enim justo, rhoncus ut, imperdiet a, venenatis vitae, justo

E-Mobilty Broschüre

Titel des Dokuments (de) Donec pede justo, fringilla vel, aliquet nec, vulputate eget, arcu. In enim justo, rhoncus ut, imperdiet a, venenatis vitae, justo