Industry/Process/Application

Intro Text, Trend, Teaser

Fatti chiave dell'applicazione

Settore

Test dei componenti HV nella mobilità elettrica

Applicazione

Simulazione delle variazioni di temperatura per il test dei sistemi di gestione delle batterie (BMS)

Parametro misurato

Segnale standard 0-10 V per la funzione di controllo

Requisiti principali

Qualità con la conversione del segnale delle temperature simulate, in modo da poter valutare le prestazioni del BMS.

Sicurezza grazie all'isolamento completo delle tensioni pericolose presenti tra il BMS e l'hardware di prova.

Simulazione per la valutazione dei BMS

Descrizione dell'applicazione

La durata della batteria di un veicolo elettrico è influenzata in modo significativo dalla qualità del sistema di gestione della batteria (BMS).

In ogni singola cella della batteria vengono monitorati parametri quali la corrente di carica/scarica, la tensione e la temperatura. È particolarmente importante capire come il BMS risponde alle variazioni di temperatura di ogni singola cella.

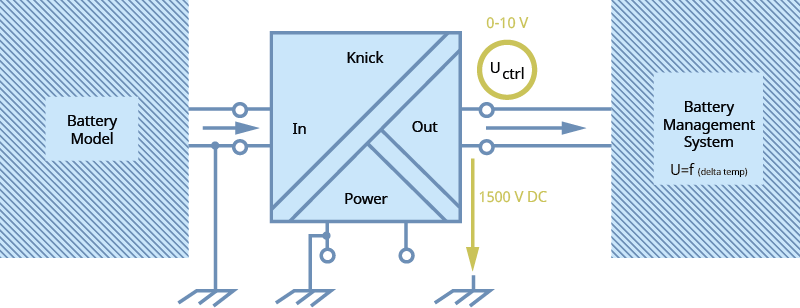

Valutare le prestazioni del BMS collocando un pacco batterie in una camera climatica per sottoporlo all'intera gamma di temperature è costoso e richiede molto tempo. Per questo motivo, le variazioni di temperatura vengono spesso simulate. I sistemi di prova generano tensioni di controllo in un modello di batteria che aiutano a valutare la gestione della temperatura del BMS. Questi sistemi sono tipicamente esposti a tensioni CC elevate, in quanto la batteria e il suo sistema di gestione lavorano in ambienti in cui le tensioni superano gli 800 V CC... e continuano a salire grazie ai progressi della tecnologia.

Requisiti dell'applicazione

È importante disporre di precisione e sicurezza nelle conversioni dei segnali di tensione necessarie per fornire condizioni di temperatura simulate ai sistemi di gestione delle batterie.

È inoltre utile disporre di una certa flessibilità nella selezione degli ingressi e delle uscite, in quanto i cambiamenti negli scenari di test potrebbero rendere necessarie modifiche alla gamma o ai tipi di segnali stessi. La flessibilità comporta anche la possibilità di standardizzare un'unica soluzione per le diverse applicazioni di condizionamento e isolamento presenti negli ambienti di test.

Perché Knick?

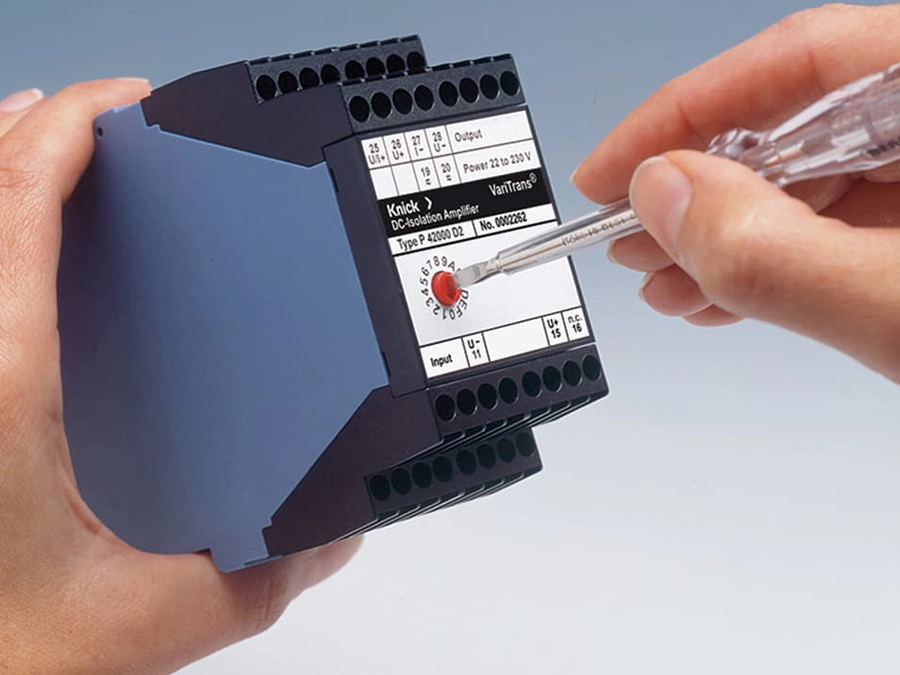

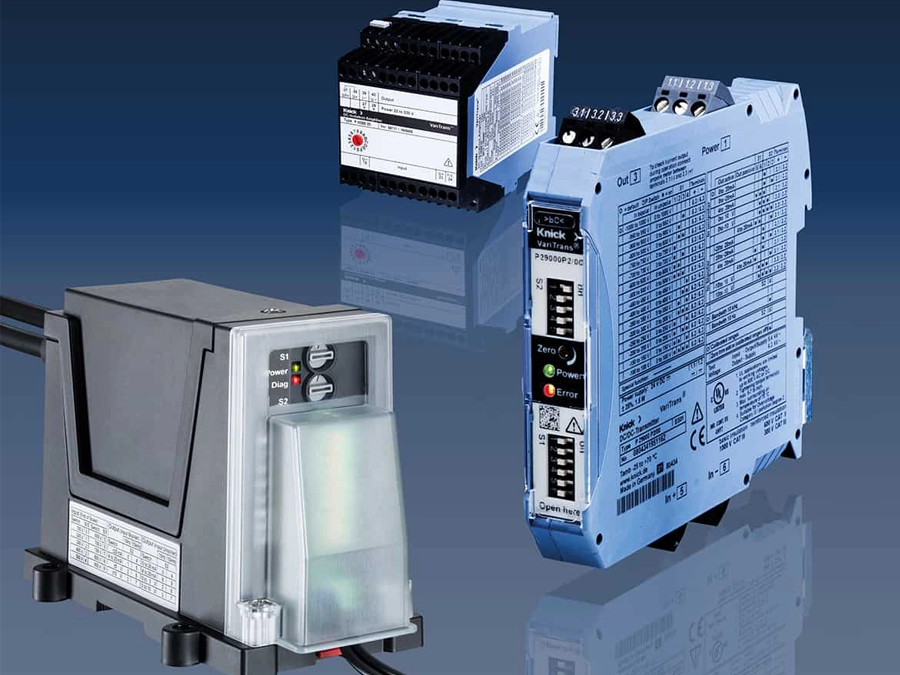

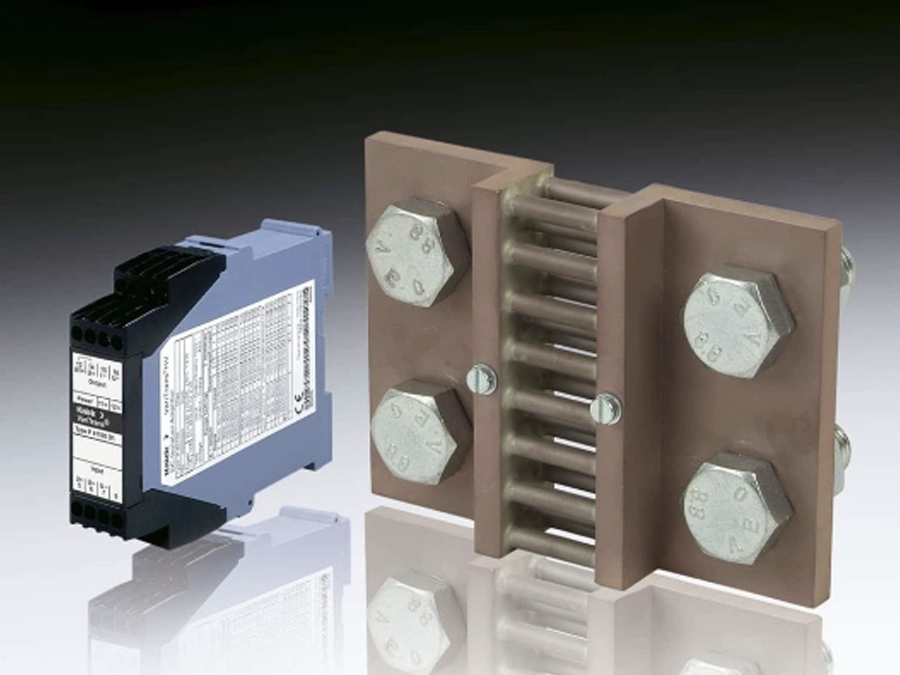

Il Knick P41000 è in grado di convertire segnali di controllo standard dall'ingresso all'uscita, mantenendo tutti i canali isolati elettricamente tra loro, fino a 1650 V CC. Il tempo di risposta T90 è di 110 μs e il dispositivo ha una frequenza di taglio di 5 kHz. La flessibilità è ottenuta grazie alla commutazione calibrata di un massimo di 16 gamme di ingresso/uscita, che possono essere definite dall'utente.

Headline H2

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet.

Headline H3

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet.

Prodotti correlati

Industrie e applicazioni correlate

E-Mobilty Broschüre

Titel des Dokuments (de) Donec pede justo, fringilla vel, aliquet nec, vulputate eget, arcu. In enim justo, rhoncus ut, imperdiet a, venenatis vitae, justo

E-Mobilty Broschüre

Titel des Dokuments (de) Donec pede justo, fringilla vel, aliquet nec, vulputate eget, arcu. In enim justo, rhoncus ut, imperdiet a, venenatis vitae, justo