프로세스 분석

Monitoring CIP/SIP processes

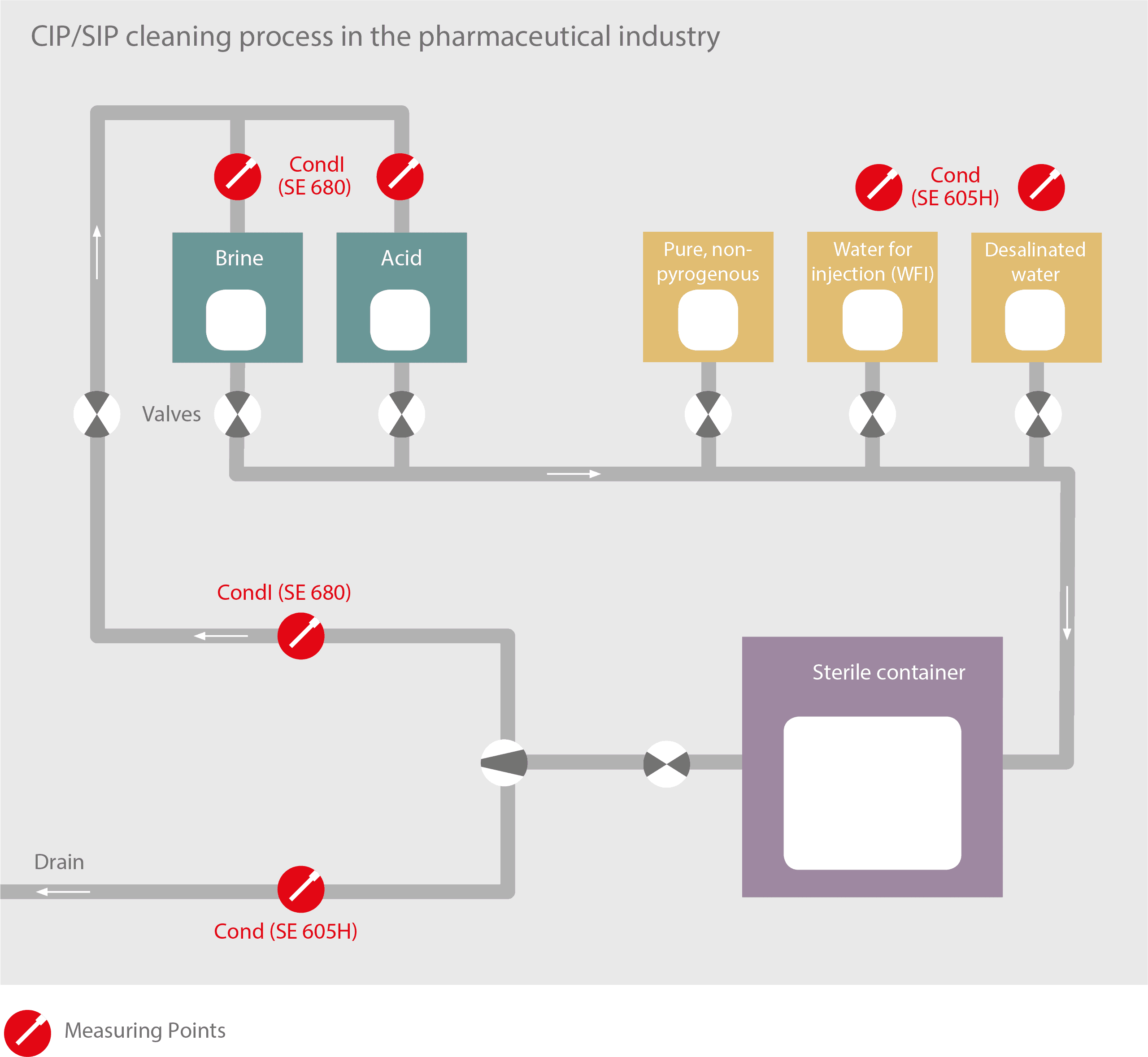

In pharmaceutical, biological or process systems for food production, all process-wetted system components must be cleaned and sterilized at regular intervals. For this reason, during the cleaning in place (CIP) and sterilization in place (SIP) all relevant tubes and containers are rinsed and disinfected with the alkaline and acidic cleaning agents compatible with the process.

In SIP, process systems are also sterilized with superheated steam for 100% sterilization. The conductivity sensors for monitoring the cleaning process and cleaning agent concentration in the rinsing water must often resist extreme temperature fluctuations and aggressive cleaning agents.

Reliable conductivity measurement in cases of extreme temperature fluctuation

In CIP, coarse contamination is first removed by pre-flushing with water and cleaning agents and then flushed again to remove residual cleaning agent. Next, acidic cleaning solutions are used to remove lime and other mineral deposits. In the last steps, disinfectants are introduced and flushed out with ultrapure water in the final rinse.

In this cleaning procedure, after each step the conductivity of the rinsing water must be measured as a means of providing information on the remaining foreign substances in the water. If the measured values do not match the required specifications, the relevant step is repeated until the setpoints are present.

The SIP process follows. In it, the process system is not only disinfected but also sterilized by introducing ultrapure, non-pyrogenous steam (>120 °C). Depending on the specific processes, batch size and product variance, some systems must be cleaned and sterilized several times a day – in some cases, every hour.

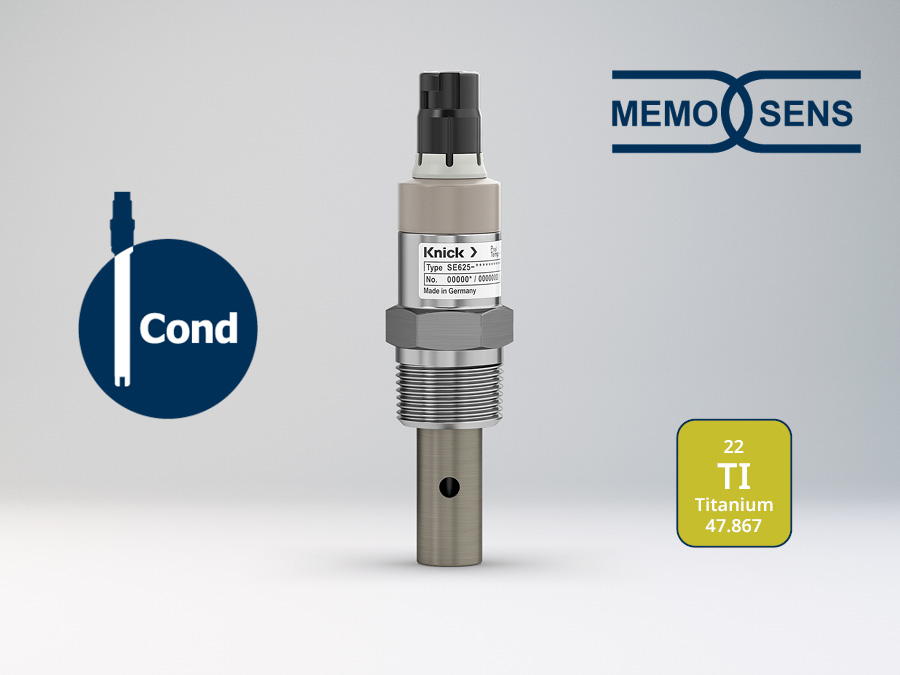

The conductivity sensors used in SIP are exposed to extreme temperature fluctuations of ≥ 120 °C in a moist environment. Conductivity sensors must have robust and hygienic designs. They must also be equipped with industry-specific process connections and be made of FDA-compliant materials

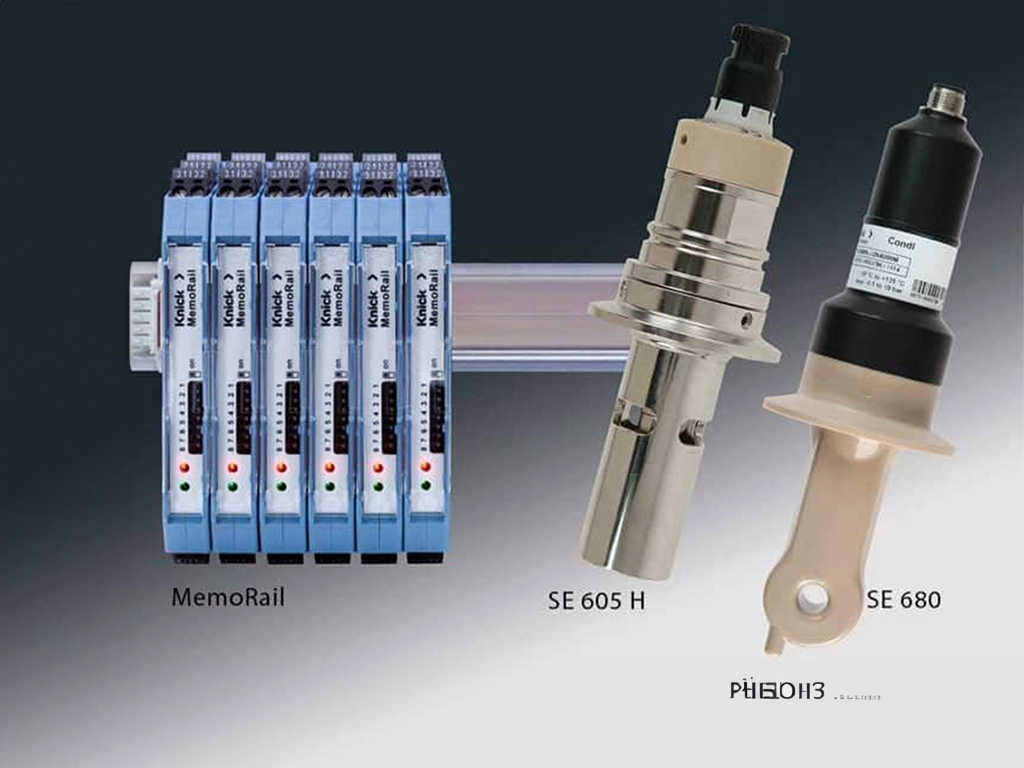

The SE680 hygienic, inductive conductivity sensor for monitoring CIP rinsing circuits features an extremely broad measuring range of 0 … 2000 mS/cm at a resolution of 2 μS/cm. The sensor seamlessly monitors the entire cleaning process.

SE680 is extremely resilient – particularly in pharmaceutical sector applications – thanks to its lack of seals, joints and gaps and dirt-repellent surface made of FDA-approved Virgin PEEK.

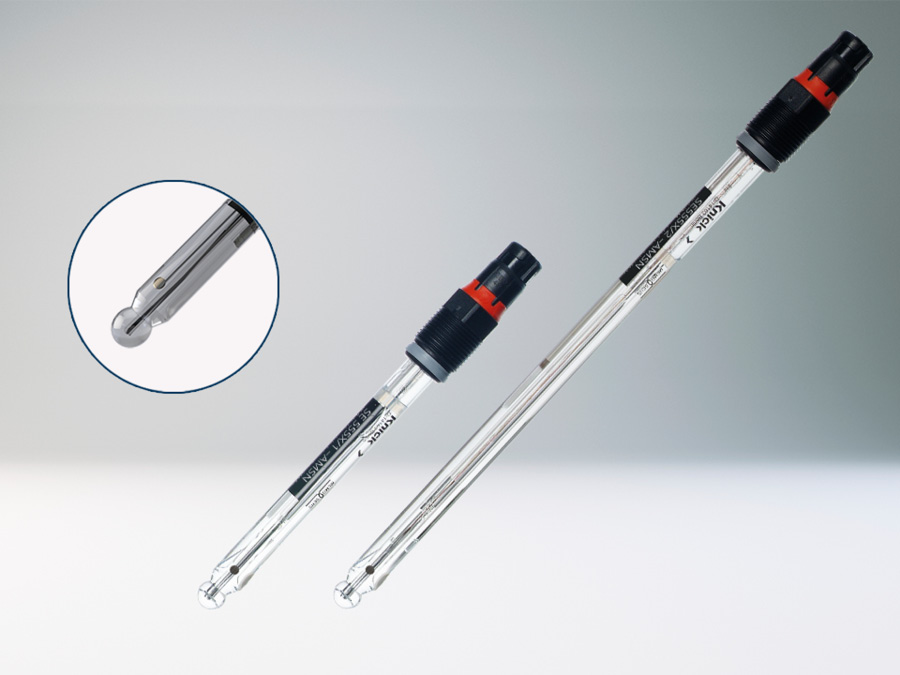

During the final rinse with WFI (water for injection), the ultrapure water must have a non-temperature-compensated conductivity value of < 2.7 μS/cm, as a rule. Higher values indicate that there is residue in the water and another rinse is required.

Designed for the ultrapure water measuring range of 0.001…600 μS/cm, the SE605 H conductive conductivity sensor is used to monitor the final rinse. The SE605H has a hygienic design with two coaxially arranged electrodes made of electropolished stainless steel 1.4435 with a roughness depth of < 0.4 μm or < 0.8 μm. All of the materials used are FDA-compliant.

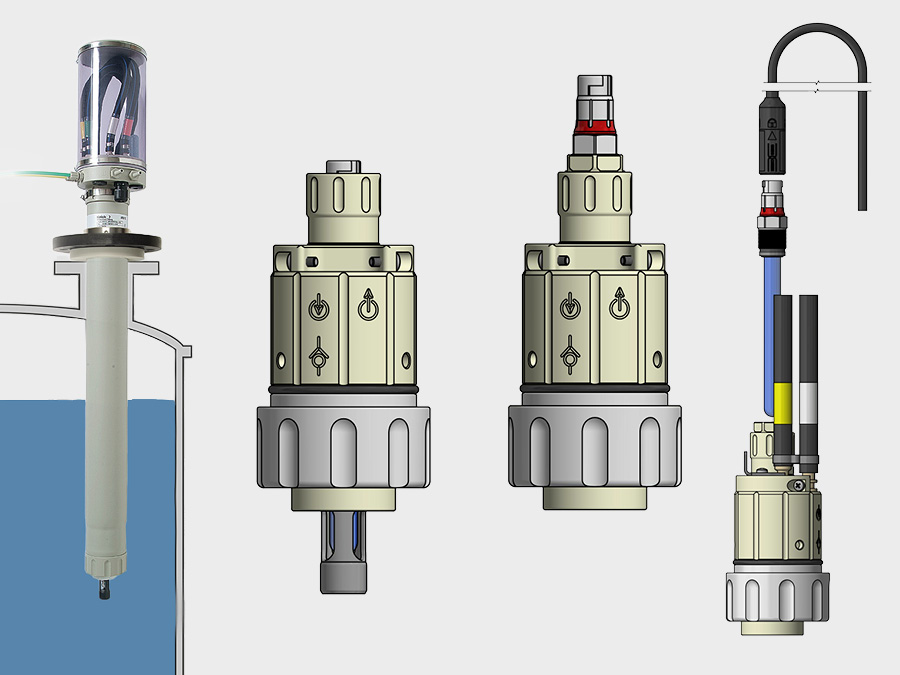

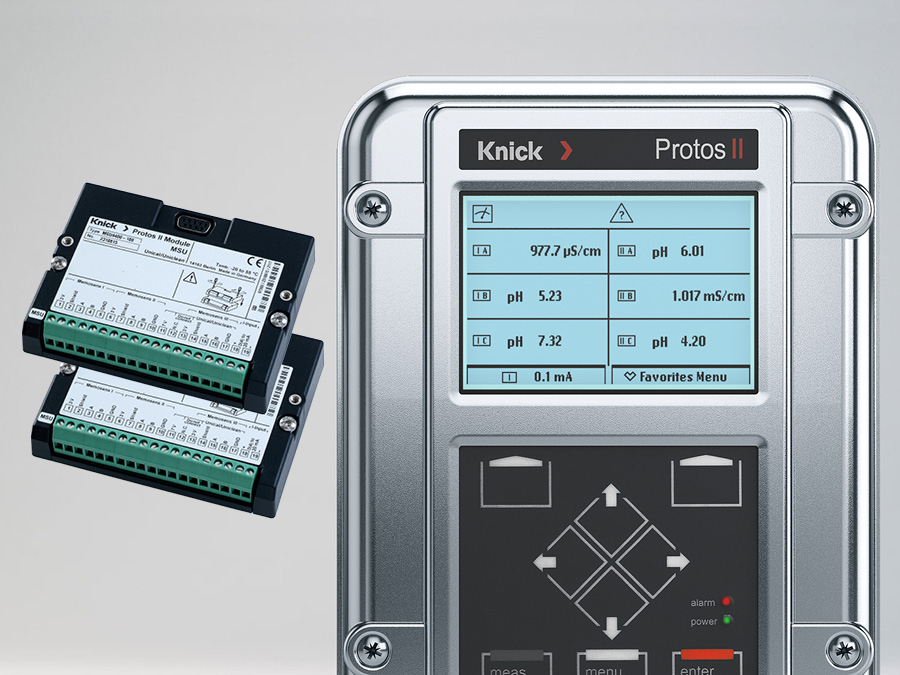

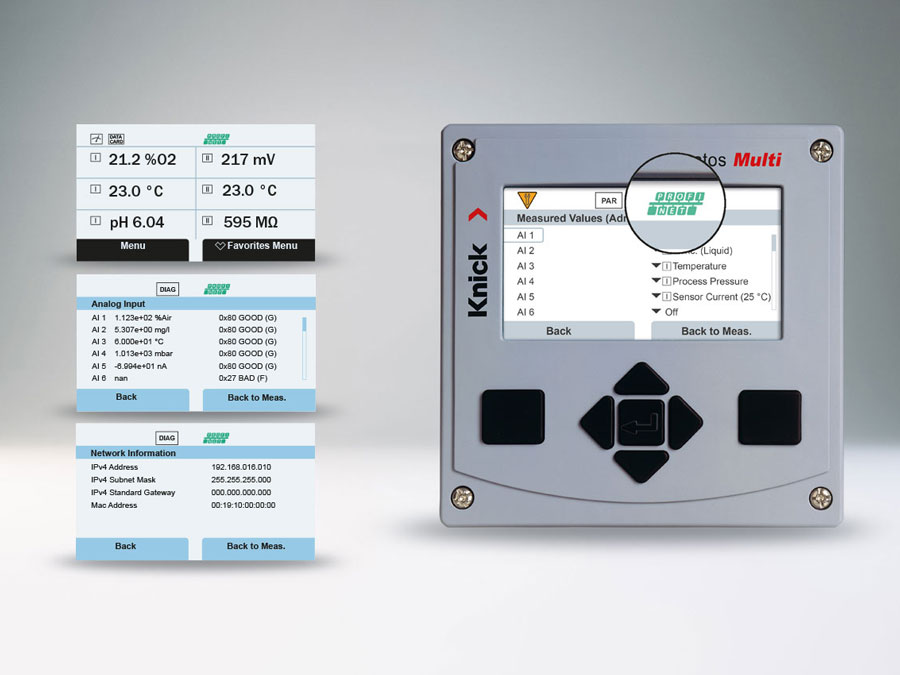

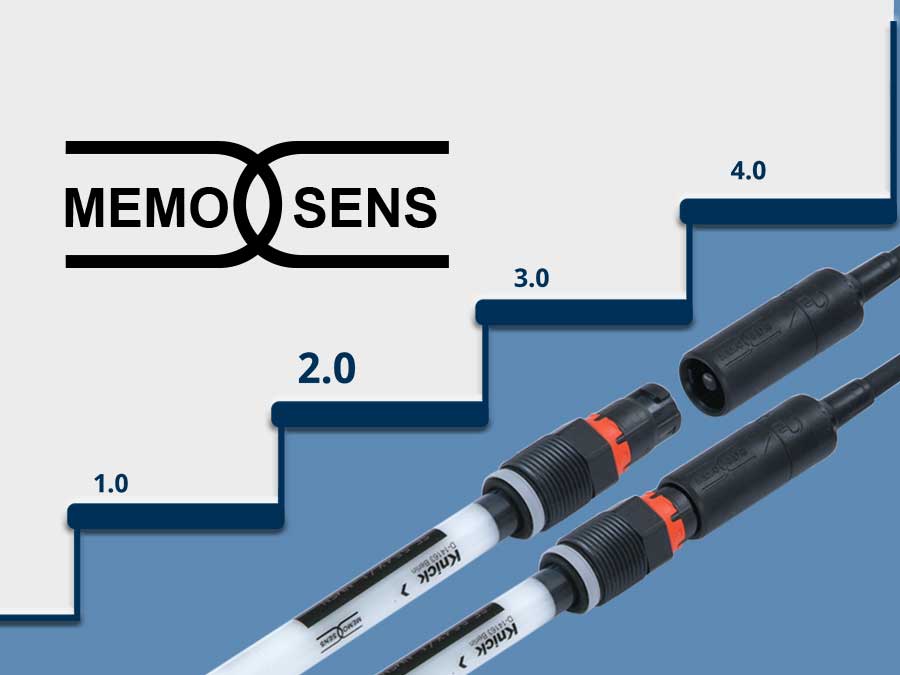

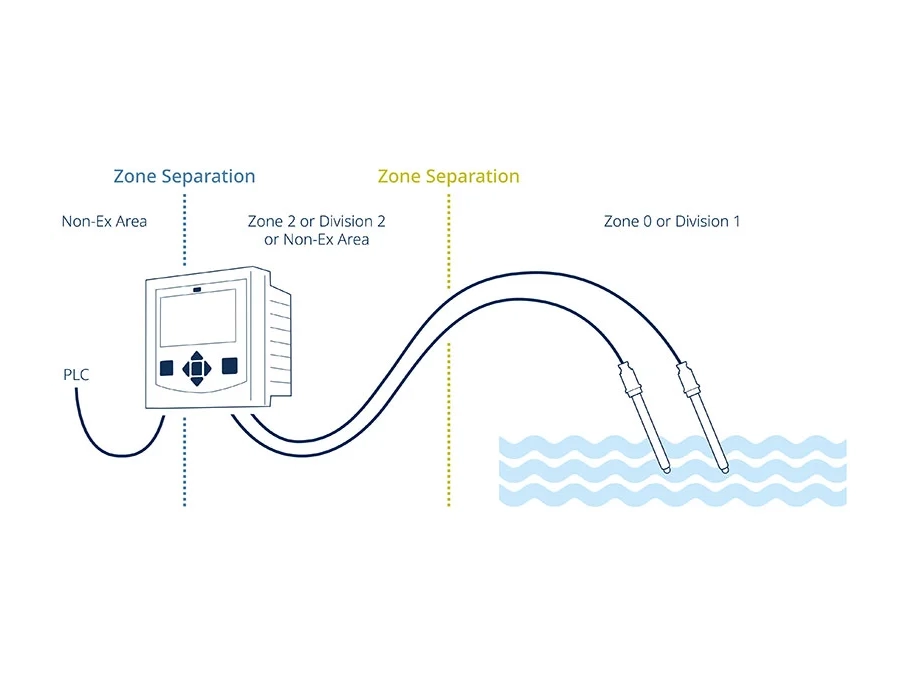

MemoRail analyzers are available for transferring measured values from the Memosens sensors to the control system. They transmit sensor and temperature values via a 4-20 mA output signal directly to the control system. A MemoRail variant with an interface for Modbus-based control systems is also available. A multi-parameter device in a compact, space-saving modular housing that comes in a 1- or 2-channel version, universal-use MemoRail is suitable with all Memosens sensors for measuring pH/ORP, oxygen and conductivity.

Return on Investment

- Measuring loop cost-effectiveness is the focus of Memosens technology. Using Memosens significantly reduces investment costs for process analytics. Two 2-channel Memosens sensors can be connected to the MemoRail multi-parameter analyzer at the same time. The slim, compact modular housing simplifies installation in any system, even in tight installation spaces. The measurement signals are transmitted directly to the control system via -20 mA or Modbus.

- Memosens also reduces and simplifies measuring loop maintenance, since the calibration data of Memosens sensors is saved directly in the sensor head. These robust, digital conductivity sensors monitor processes reliably and precisely.